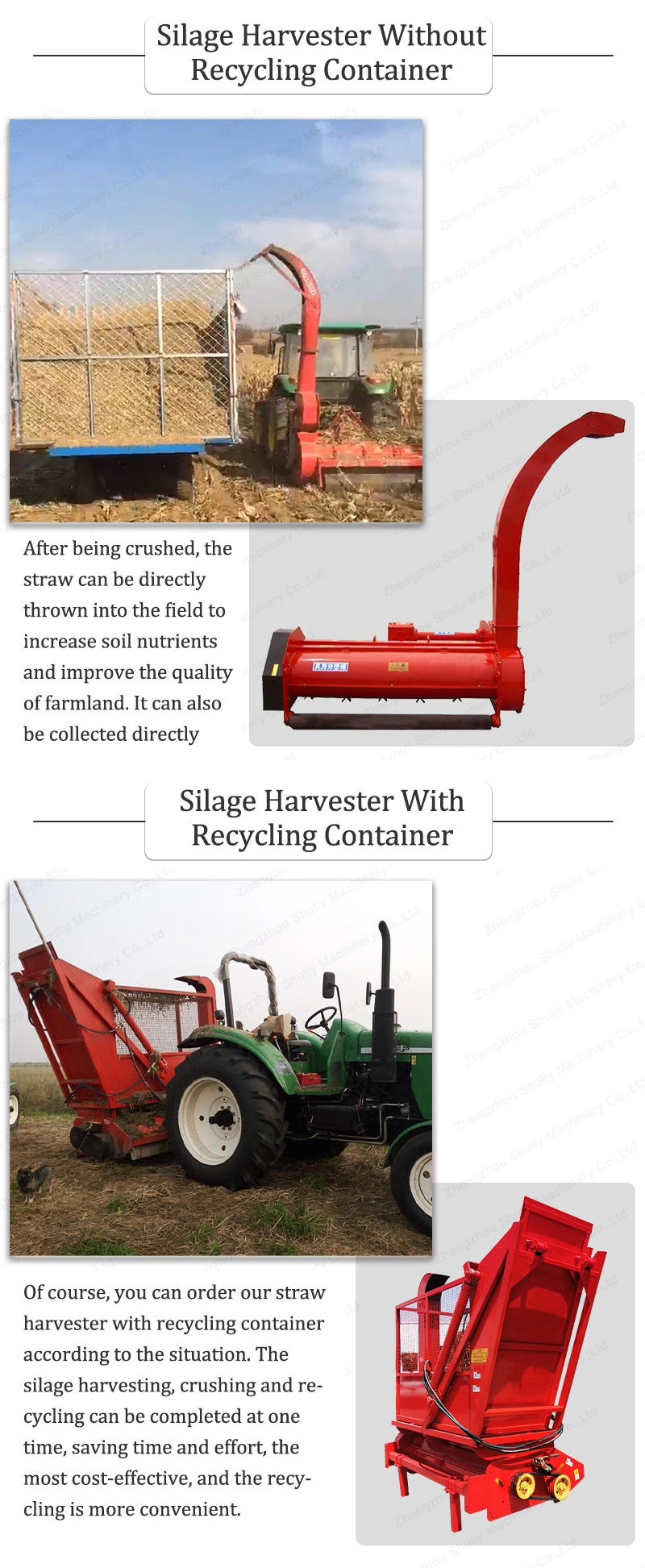

Introduction of straw silage recycling harvester

1. The machine mainly consists of suspension part, variable speed transmission part, cutting and crushing part, recycling and conveying part, and fan part.

2. The straw crushing and recycling machine integrates harvesting, cutting, crushing, throwing, and recycling. It realizes the purpose of multi-purpose, low consumption, high efficiency, and comprehensive utilization of biomass energy. It has far-reaching significance for the development of biomass energy projects.

3. The machine is easy to maintain and low in price. It is ideal matching equipment for breeders and farms of various specifications.

Grain stalk such as corn straw, sorghum straw, and other grasses all can be the raw

materials.

Work process of straw silage harvester

1. Firstly the operator connects the silage harvester machine with a tractor.

2. rotating blades constantly cut the straw when it begins to work.

3. The straw goes into the crushing part.

4. Then the fan blows the small pieces into the lifter.

5. Lifter conveys the small pieces into the container.

6. Finally, the hydraulic device on the tractor powers machine to unload the crushed straw. We have many models of silage harvester corn forage machines for you to choose from.

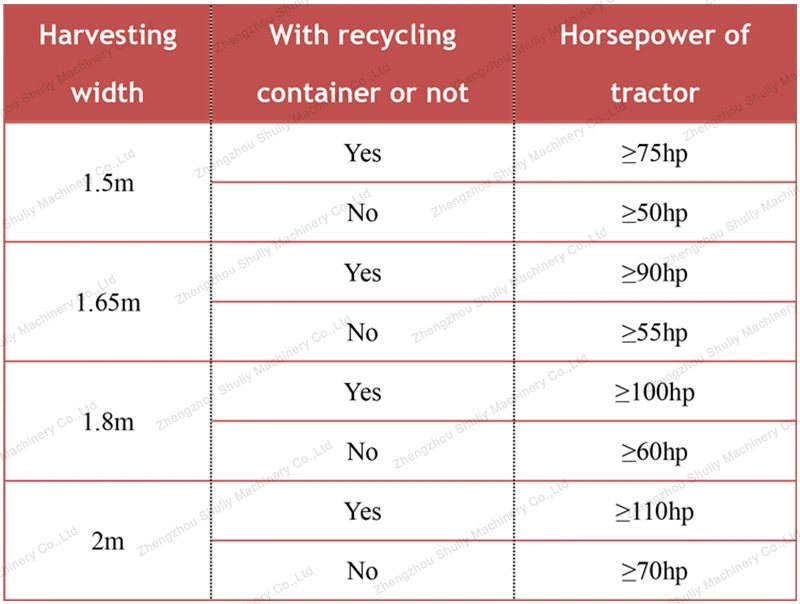

We have many models of silage harvester corn forage machines for you to choose from.

Each one has different harvesting ranges. The tractor horsepower for different harvesting widths is different.please contact us to know more.

Technical parameters of multifunctional forage silage harvester

Model | 4JQH-135 | 4JQH-150 | 4JQH-165 | 4JQH-170 | 4JQH-180 | 4JQH-200 |

Size(m) | 1.5*1.81*3.35 | 1.48*1.98*3.5 | 1.48*2.13*3.5 | 1.48*2.18*3.5 | 1.48*2.28*3.5 | 1.68*2.46*3.36 |

Weight(kg) | 640 | 700 | 790 | 820 | 980 | 800 |

Capacity(hm²/h) | 0.25-0.48 | 0.3-0.5 | 0.32-0.55 | 0.35-0.58 | 0.36-0.6 | 0.36-0.72 |

Harvesting width(m) | 1.35 | 1.5 | 1.65 | 1.7 | 1.8 | 2 |

blade Quantity | 32 | 40 | 44 | 44 | 48 | 52 |

Power(kw) | 29.4-44.1 | 40-51 | 40-59 | 45-62 | 48-66 | 66.2-88.2 |

Recycling rate | ≥80% | |||||

Fling distance(m) | 3- 5 | |||||

Fling height(m) | ≥2 | |||||

crushed straw length(mm) | ≤80 | |||||

Stubble height(mm) | ≤150 | |||||

ground clearance(mm) | ≥320 | |||||

Cutter shaft speed(r/min) | 2160 | |||||

Working speed(km/h) | 2-4 | |||||

This year, our customers from Pakistan and Ecuador had ordered 10 sets of straw cutter machines with great satisfaction. He asked us for many details such as cutting width, tractor, recycling rate, etc. We aim to solve every problem our customer has and provide the best service. Influenced by patience and professional skills, he introduced our machine to his friends after receiving the machine.

Zhengzhou Shuliy machinery Co., Ltd. We not only provides customers with good quality and cost-effective products, but also provides first-class service support and solutions. Our agricultural machinery have always been very popular in Africa, South East Asia, and the North American market and have won wide praise from customers. Perfect after-sales service system allows you to worry-free.